STRUCTURES

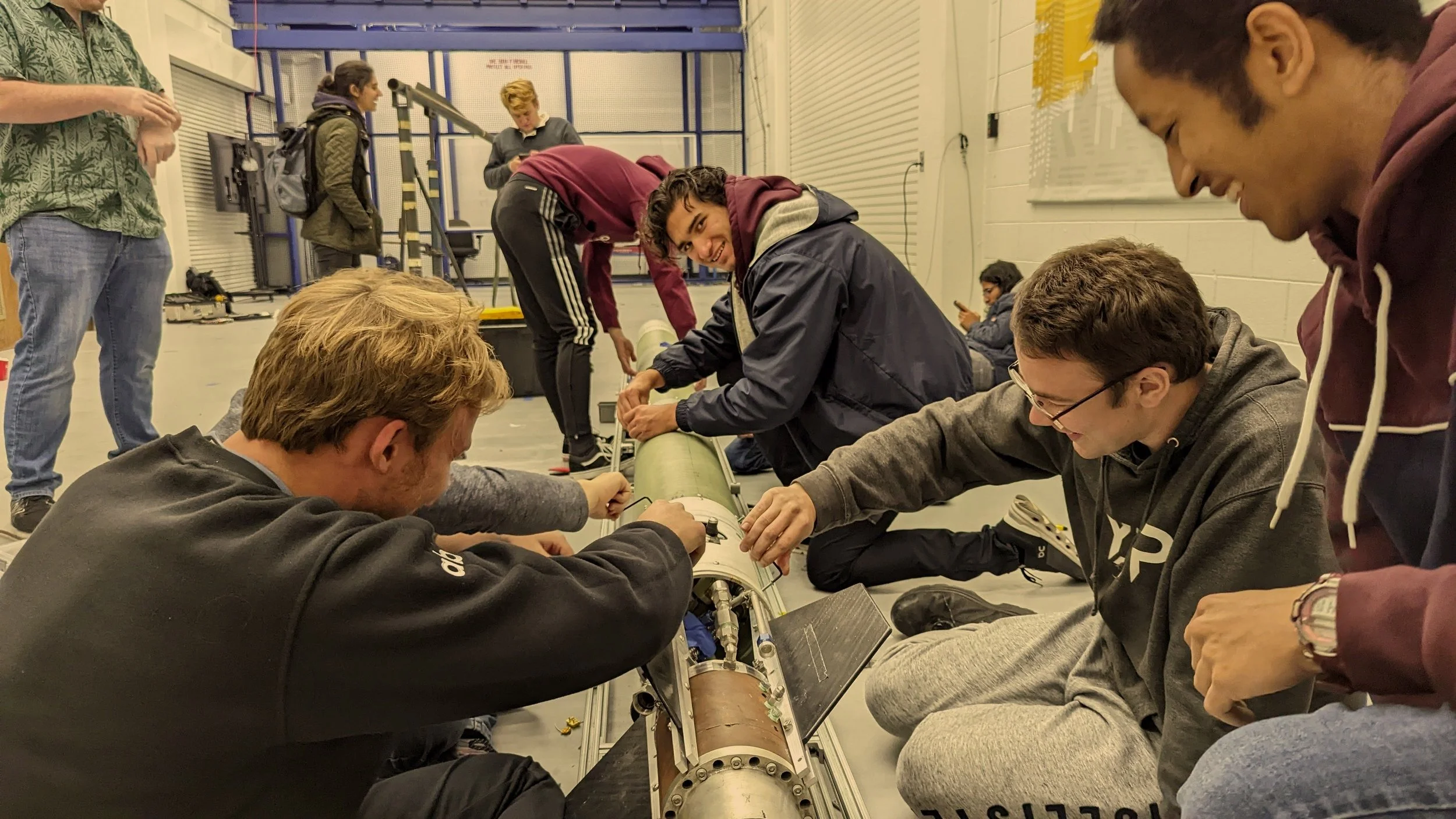

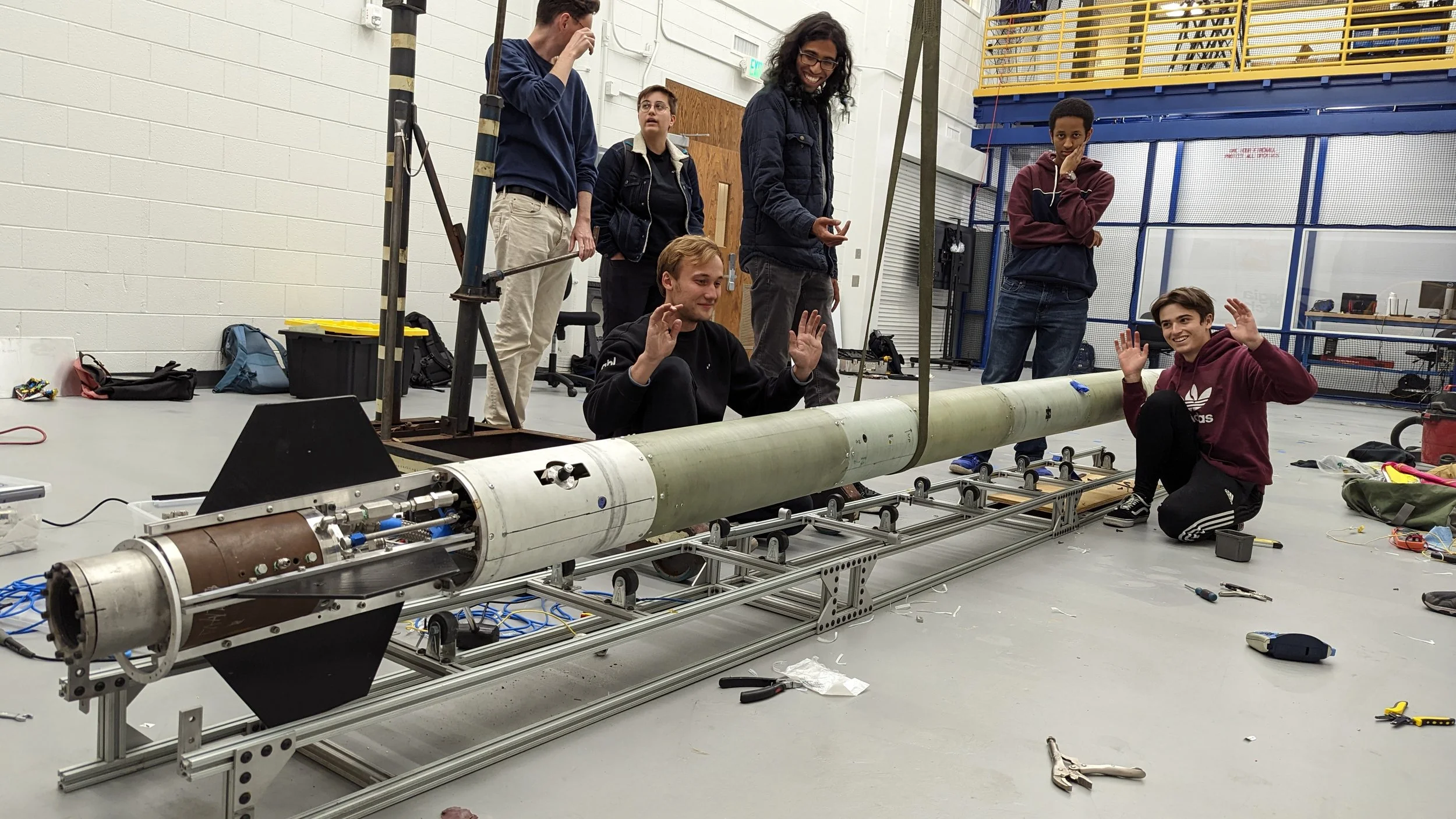

The Structures team designs and manufactures the entire vehicle structure. Everything from the nosecone to the fins are designed, built, and optimized for flight. The team works with composite structures, metal machining and welding, and integrates large assemblies. The work done by the Structures team is not limited to the vehicle - the ground support equipment and vehicle static fire test stand are also critical structures allowing for our vehicles to perform integrated static fire tests prior to launch.

Join the Structures team!

Structures is always looking for more mechanically-minded members interested in learning about CAD, structural analysis, machining, FEA, design optimization, and structural testing.

SUBTEAMS

Vehicle Structures

The vehicle structure from top to bottom is comprised of a nosecone, recovery bay, avionics bay, pressurant airframe, intertank section, propellant tanks, thrust structure, and fin can. The structures team works on all these parts and works closely with other teams to integrate all vehicle systems together.

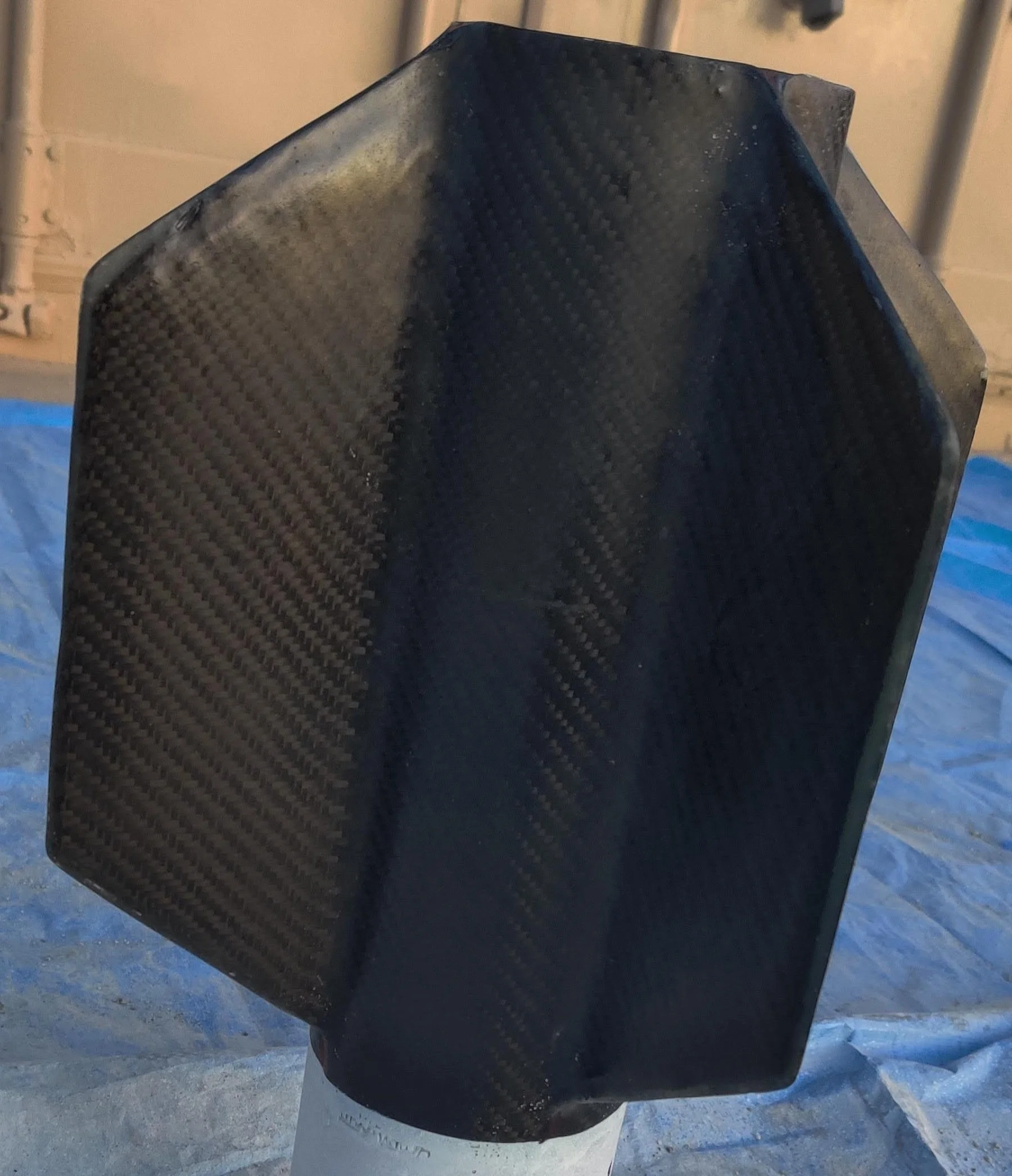

Composites

The composites team manufactures custom layups with carbon fiber and silica to make highly mass efficient structures. Composites are primarily used to make our custom nosecone and fin can structures.

Ground Structures

There are several ground structures projects which all play a vital role in preparing our vehicle for launch. The vehicle static fire stand allows for the fully integrated vehicle to perform engine tests on the ground prior to launch. The ground support equipment (GSE) fills the rocket with propellant prior to launch. The vehicle integration table is a large ground structure used to assemble the entire vehicle with ease.