Darcy II Fin Can

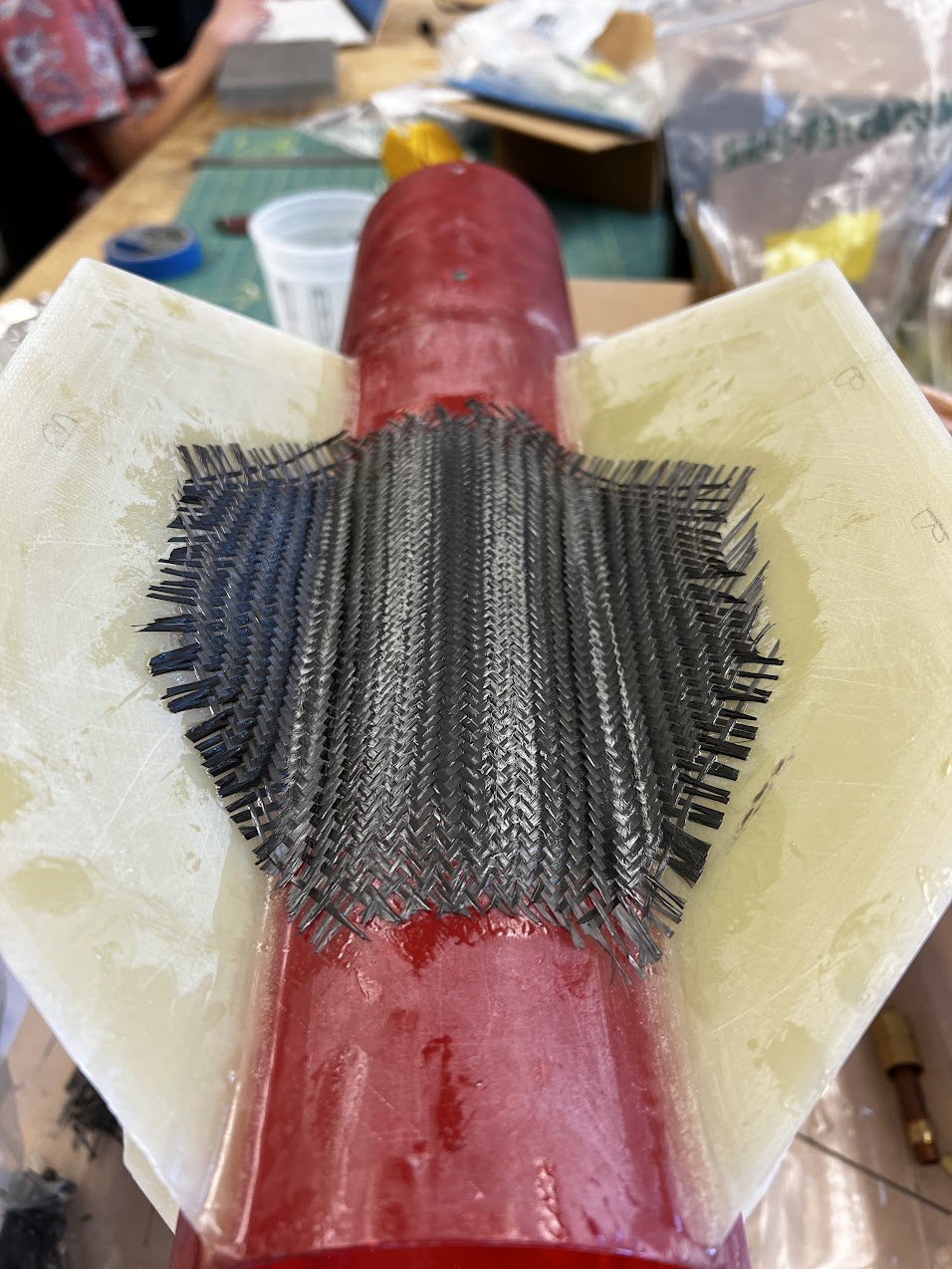

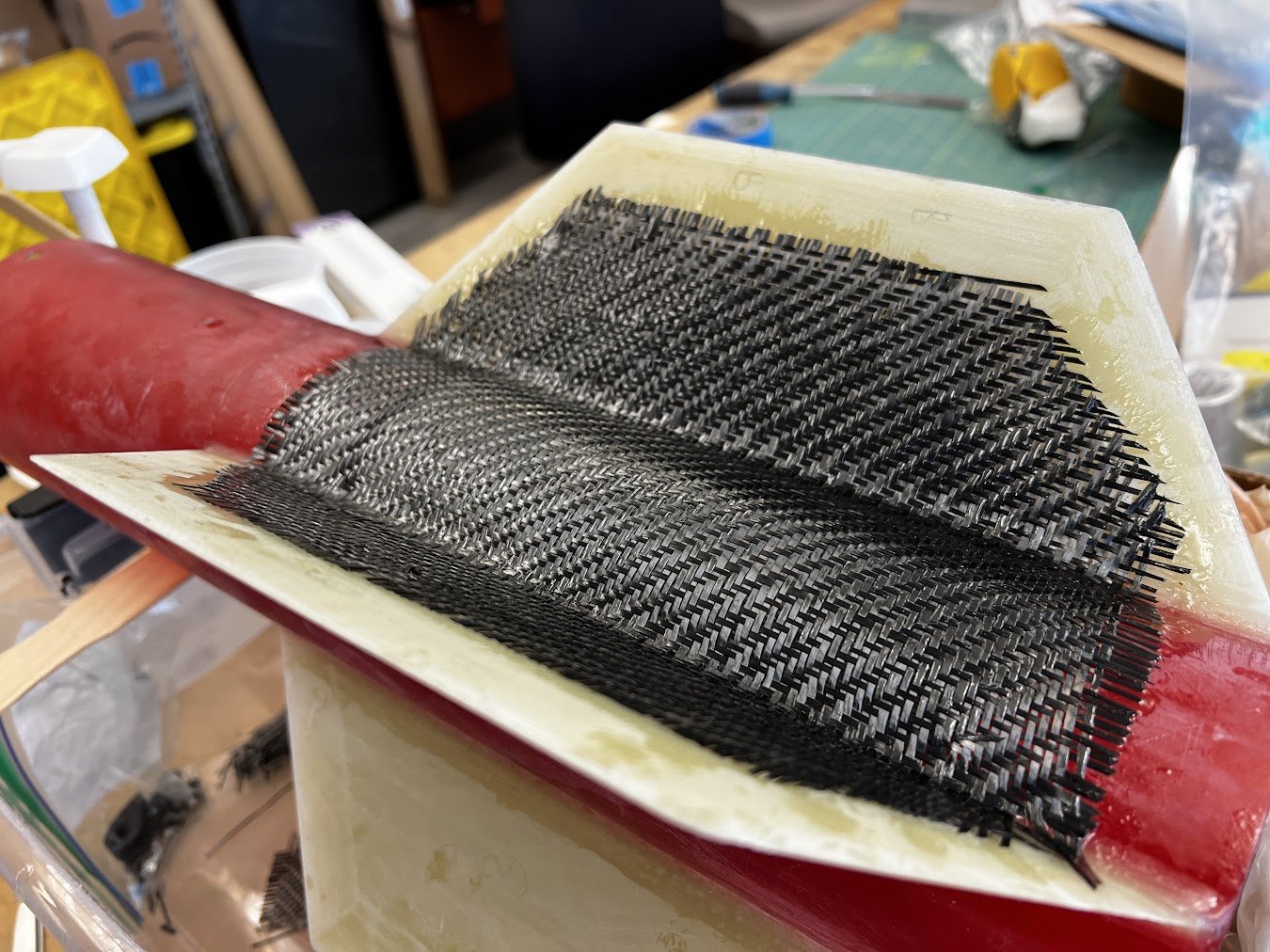

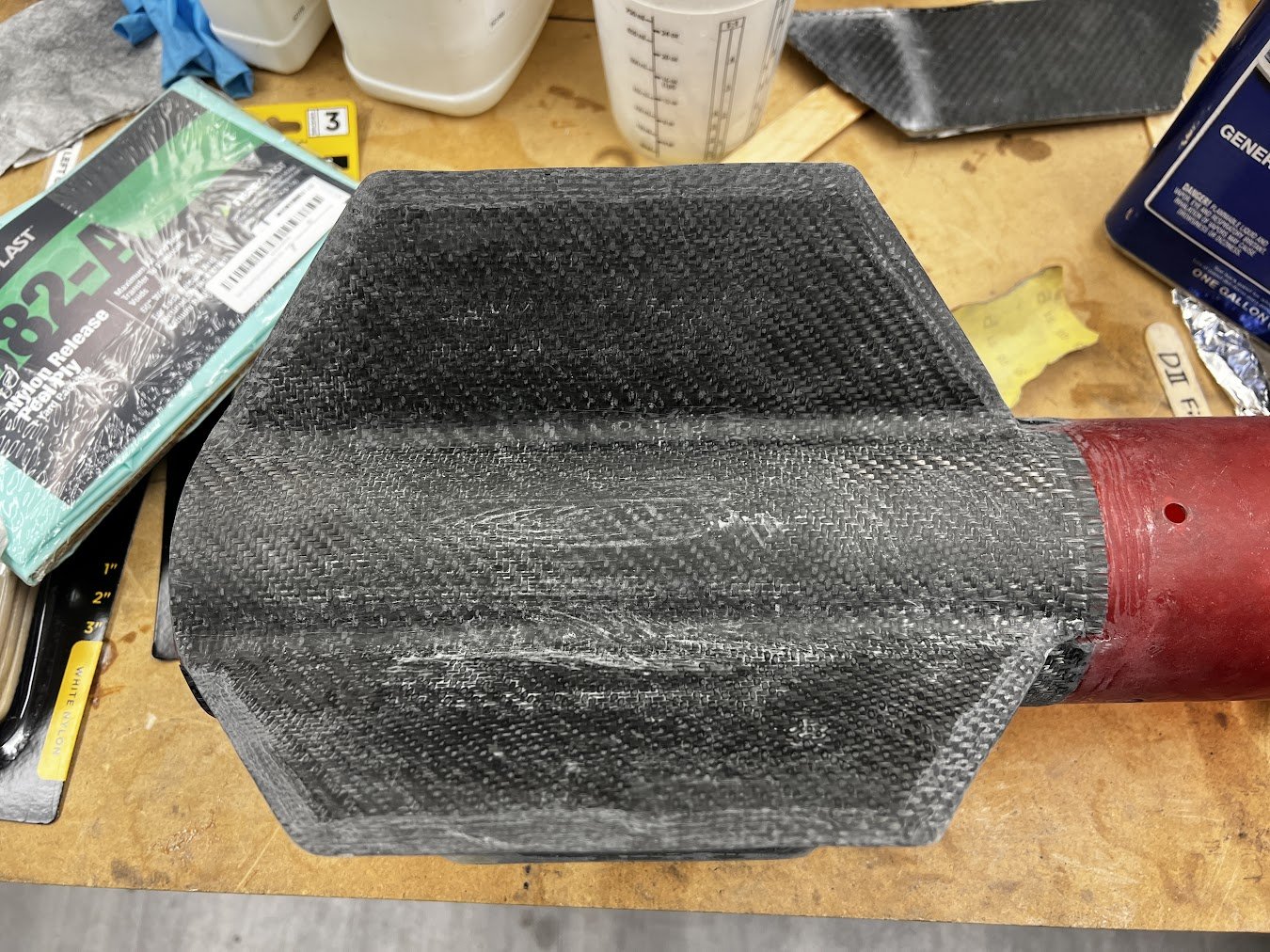

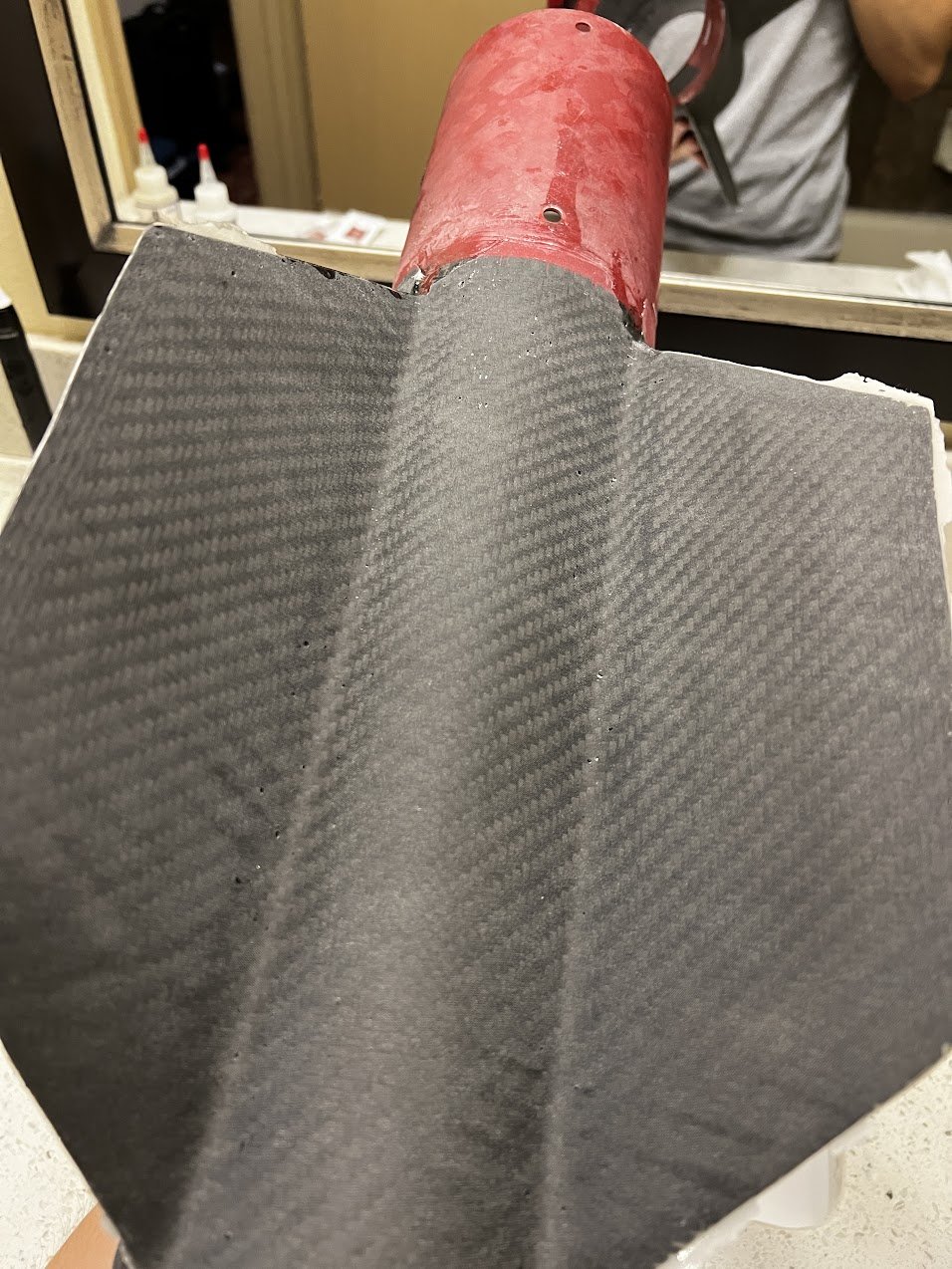

Composite layups are a fantastic choice for fin can manufacturing due to their high strength and stiffness, as well as low mass and volume compared to bolted metal fins. In its first two iterations, Darcy II utilized a fiberglass layup for its fin can, sandwiching fiberglass cores between 8 total layers of fiberglass fabric and epoxy. To improve stiffness (and aesthetics), the layup was switched to one with 12 layers of carbon fiber sandwiching the same fiberglass cores. Future layups will build upon the lessons learned with this component and will improve the fiber/resin ratio, curing processes, geometric complexity, and manufacturing efficiency.